CUSTOM ORB®

Manufactured in Tasmania

Product Description and Features

The original Australian corrugated roof sheeting and wall cladding ideal for modern and traditional architecture in residential and commercial applications.

- A lightweight yet strong roofing and walling material

- Versatile – Can be laid flat or sprung curved

- Nominal cover width: 762mm

- Minimum roof slope: 5°

Lengths

Sheets are supplied custom cut to length. Minimum and maximum lengths apply. Please contact your nearest Lysaght or TRC office in your region for more information.

Tolerance (CUSTOM ORB & CUSTOM BLUE ORB)-flat

Length: + 10 mm, – 10 mm

Cover Width: + 4 mm, – 4 mm

CUSTOM ORB Material Specification

- Next generation ZINCALUME® aluminium/zinc/magnesium alloy coated steel complies with AS 1397:2011 G550, AM125 (550 MPa minimum yield stress, 125 g/m² minimum coating mass).

- COLORBOND® steel is prepainted steel for exterior roofing and walling. It is the most widely used. The painting complies with AS/NZS 2728:2013 and the steel base is an aluminium/zinc alloy-coated steel complying with AS 1397:2011. Minimum yield strength for CUSTOM ORB is G550 (550 MPa). Minimum coating mass is AM100 (100 g/m²).

- COLORBOND® Metallic steel is prepainted steel for superior aesthetic qualities displaying a metallic sheen.

- OLORBOND® Ultra steel is prepainted steel for severe coastal or industrial environments (generally within about 100–200 metres of the source). The painting complies with AS/NZS 2728:2013 and the steel base is an aluminium/zinc alloy-coated steel complying with AS 1397:2011. Minimum coating mass is AM150 (150 g/m²). Minimum yield strength for CUSTOM ORB is G550 (550 MPa). Minimum coating mass is AM150 (150 g/m²).

- COLORBOND® Stainless steel is pre-painted steel and is used for severe and coastal environments. The painting complies with AS/NZS 2728:2013 and the steel base is a stainless steel complying with AISI/ASTM Type 430; UNS No. S43000.

Masses CUSTOM ORB

| BMT | kg/m | kg/m² | m²/t | |

| 0.42 | ZINCALUME® | 3.26 | 4.28 | 234 |

| 0.42 | COLORBOND® | 3.32 | 4.35 | 230 |

| 0.48 | ZINCALUME® | 3.70 | 4.86 | 206 |

| 0.48 | COLORBOND® | 3.76 | 4.93 | 203 |

Schematic

Span Tables

The maximum recommended support spacings are based on testing in accordance with AS1562.1-1992, AS4040.1-1992 and AS4040.2-1992.

Roof spans consider both resistance to wind pressure and light roof traffic (traffic arising from incidental maintenance).

Wall spans consider resistance to wind pressure only.

| TYPES OF SPAN | BMT (MM) | |

|---|---|---|

| 0.42 | 0.48 | |

| ROOFS | ||

| Single Span | 700 | 800 |

| End Span | 900 | 1300 |

| Internal Span | 1200 | 1700 |

| Unstiffened Eaves Overhang | 200 | 250 |

| Stiffened Eaves Overhang | 300 | 350 |

| WALLS | ||

| Single Span | 1800 | 1800 |

| End Span | 2500 | 2700 |

| Internal Span | 2700 | 2700 |

| Overhang | 200 | 250 |

- For roofs: the data are based on foot-traffic loading.

- For walls: the data are based on pressures.

- Table data are based on supports of 1mm BMT.

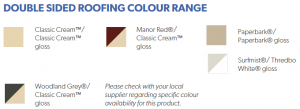

Colour Range

The LYSAGHT® Roofing & Walling Installation Manual is a guide to the design and installation of steel roofing and walling manufactured by LYSAGHT®. We intend that it be used by all trades and professions involved with specifying and applying the wide range of our products. We refer only to genuine steel roofing and walling manufactured by us and marketed under our brand names. Our recommendations should only be used for our products because they are based on comprehensive testing of our profiles, base metal thicknesses (BMT) and material finishes.

Please be aware that in some Australian states cladding must be installed by licensed tradespeople. For correct specification and installation of LYSAGHT® roofing and walling products in cyclonic areas, please download the LYSAGHT® Cyclonic Area Design Manual for Steel Roofing, Walling & TOPSPAN®.

Brochures

LYSAGHT CUSTOM ORB® and CUSTOM BLUE ORB®

WALLING SOLUTIONS DESIGN & INSTALLATION GUIDE