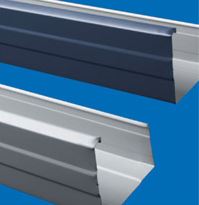

SQUARE GUTTER

Manufactured in Tasmania

SQUARE GUTTER is an appealing, modern profile that suits a multitude of building designs.

Maintain the continuity of SQUARE GUTTER profile on barges by teaming it with the SQUARE BARGE CAPPING. These products combine the low-maintenance finish and great colour choice of COLORBOND® steel with a bold profile that is buckle free even on long runs.

Colour Range

Square Gutter is available in the standard range of COLORBOND® steel colours and in unpainted ZINCALUME® steel.

Fixing to Timber Fascia

Fix a bracket at the high end of fall first, then fix a bracket at the low end of the fall. Stringline a common point on both brackets and install the remaining brackets at the required spacings (not exceeding 1200mm) with common points on the stringline. Brackets are best attached to the fascia with two 40 x 3.75mm Helical thread galvanised nails placed diagonally opposite.

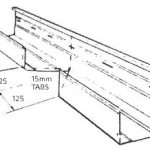

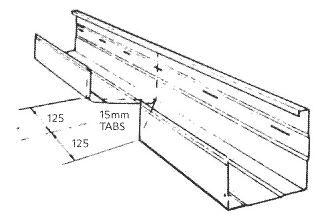

Attaching Gutter to Brackets

Hook the front of the gutter onto the end of the long arm of the brackets and slide back of gutter under the long arm until it is hard up to the back of the bracket. Push gutter into the upright position lifting the bottom of the gutter onto the platform provided by the bracket. When the gutter is in the correct position turn down both tabs of the gutter brackets onto the back of the gutter to complete the attachment.

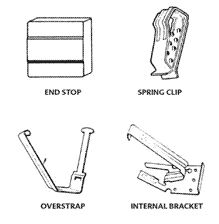

Spring Clip Systems

Fixing to metal fascia is simplified by using the spring clip which snaps over the metal fascia and has six teeth at alternative heights for the back of the gutter bead to snap into. Fall of gutter to downpipe outlet is determined by the height of the gutter attached to these teeth. The face of gutter is then supported b the overstraps which connect in front bead of gutter and top bead of fascia.

Support Recommendations

Gutter Brackets spacings should not exceed 1200mm. Where metal Fascia is used, brackets must be placed within 150mm either side of the Rafter brackets.

End Stops

Preformed End Stops provide a neat finish to straight runs of gutter. These End Stops require less labour and skill than site formed ends. Both methods of end stopping require the use of rivets and a roofing type silicon sealant.

External Corners

Cut, fold, rivet and seal.

Internal Corners

Cut, fold, rivet and seal.

Gutter Joining

To produce a slip joint, notch gutter, insert reduced end into normal end, rivet and seal.

Square Gutter Brochure